Keep it clean

To avoid introducing pests into the clean growing spaces there is a transition room situated next to the entrance. It serves to allow staff to change into clean shoes and clothing. The transition room also includes a storage space.

Processing room & SeedBox

The second room is intended for processing of seedlings as well as harvested produce. It includes a table with a stainless steel sink and storage space.

Large capacity SeedBox allows sufficient space for ongoing supply of hydroponic seedlings. Offers space for 4500 seedlings.

seedling at time

0

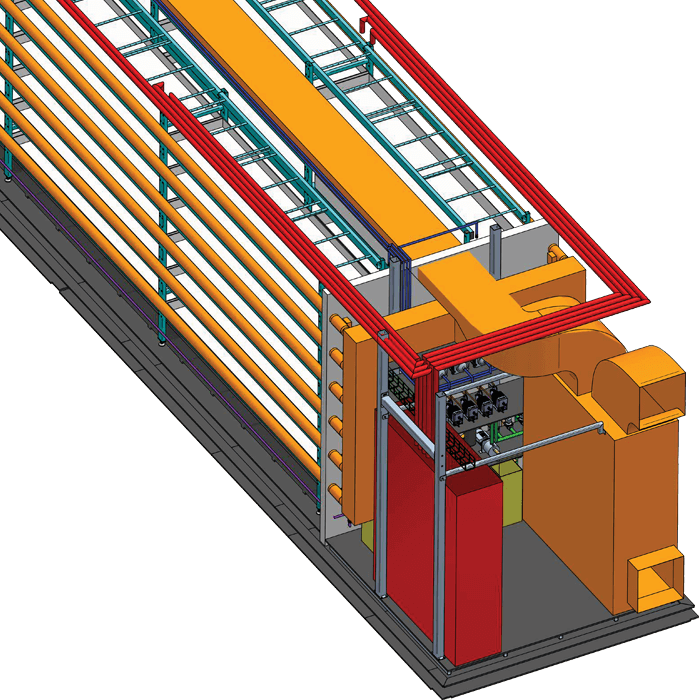

grow space

The growing area comprises six, nine or twelve metre long stainless steel racks, which can house up to 6 levels of growing space easily accessible by an adjustable electric dolly.

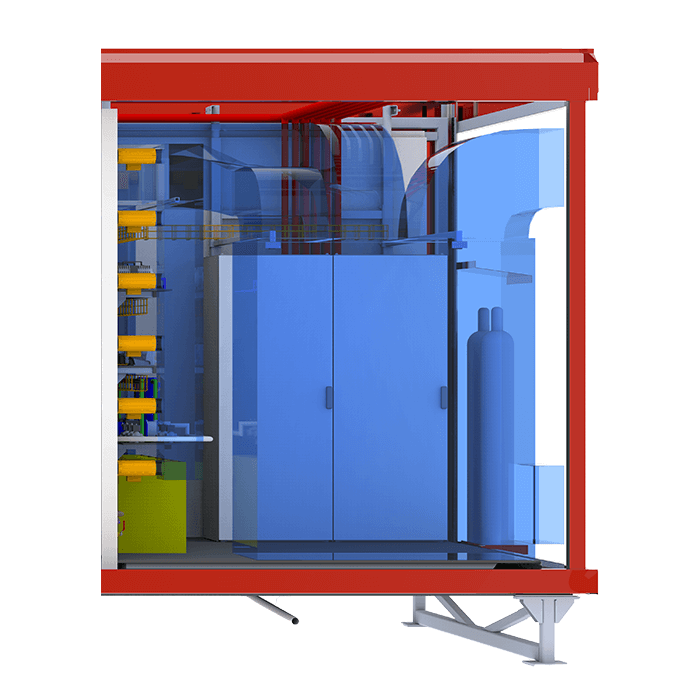

control room

Technical machinery is placed outside of the growing area in a separate control room in order to be isolated from the wet environment. Furthermore, the gardening staff has no access to these premises, as they require a higher level of skills and training. Additionally, back-up technologies are present in case of technical failures.

The control room also includes up to two independent water treatment machines and air conditioning unit specifically adapted for use in hydroponics.

Flawless air conditioning

A crucial part of the control room is an air conditioning unit specifically designed to meet our requirements.

The air circulates through fabric diffusers placed at each level of the growing area into a ceiling exhaust into a doubled ventilation unit.

BG is a closed loop system in which the air circulation is the main component of climate control. In case of high humidity the condensed water is recirculated back onto the root system of the plants and in case of temperature increase the heat is preserved for further use. External cooling is used minimally.